Traditional Kentucky Whiskey Pot Still Plans – Learn How To Build A Pot Still At Home

This guide will teach you how to build a 6 Gallon Kentucky style copper pot still. This size is perfect for anyone interested in home distilling and can be constructed by anyone with a general knowledge of soldering.

If your tired of making the same old boring neutral spirits with your reflux still and are looking to make a tasty traditional rum or whiskey moonshine this still design is for you.

This still plan is more difficult then most other plans. If you’re not up to building it check out these 5 Gallon Copper Stills on Amazon. Can’t beat the price and their well built. When I built mine it took me 30 hours and $200 in materials. The sheet of copper wasn’t cheap but I really enjoyed building my own Pot still.

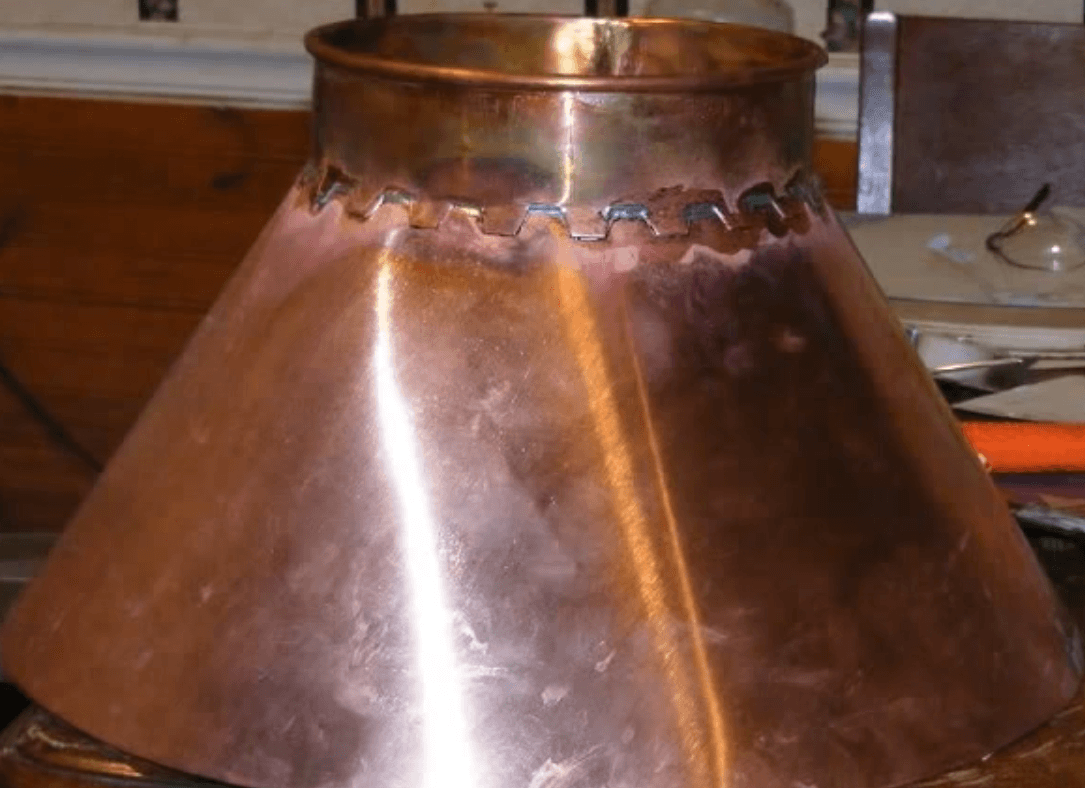

To get started let’s look at what we’re going to build. Below is a picture of the Pot still we’re going to build. This still was designed by Sherman Owen so a special thanks to him for posting his design and making the video’s I’ve shared.

You will need the following Materials and Tools:

- Half Sheet of Copper – 3 ft by 4 ft ( use 18 gauge copper) Amazon has some reasonable priced copper sheets

- Roll of Solder – Try to get hold of a roll of 95/5 tin/silver is the best and stay away from anything with cadmium/antimony or lead in it.

- Rivets – stainless steel or copper

- 1/4 ” copper tubing – 8 ft should do

- 1/2 ” copper pipe – 3 ft

- 1/2 ” Brass connector (female and male ends )

Tools Required

- Solder Gun (blow torch) with Mapp Gas

- Rivet Gun

- Tin Snips

- File ( for smoothing out edges and burrs )

- Hammer

- Scissors

- Tape

- Pencil

- Ruler

- Compass

- Pliers

Step by Step Instructions to Build the Pot Still

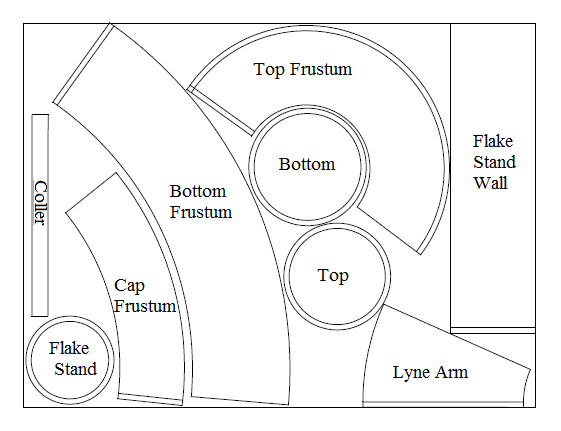

Step 1 – You will need to trace the below layout on your sheet of copper. To do this print the layout from this pdf file: 6 Gallon Copper Pot Still Template or if you want a larger still use the 12 Gallon Copper Pot Still Design Plan Template. This file contains 28 pages that should be printed and assembled these are to size for the 6 Gallon Still. Make sure your printer is set to “print actual size” . For full assembly instructions see the pdf file.

Step 2 – Cut out the shapes from the assembled template and then arrange onto the copper sheet as seen below.

Step 3 – Trace the shapes onto your sheet of copper with a pencil and then cut out shapes with your tin snips

Making the Top and Bottom Pans for the Pot Still and Condensor

Step 1 – Start with the Bottom piece. This will be your Bottom pan of the still. Find the center of the circle using a ruler and then using the compass scribe the perimeter of the pan with the compass. This should be set in 1/2 ” from the edge.

Step 2 – Using a pair of pliers create ruffles along the entire perimeter of the sheet using the scribed line as a guide

Step 3 – Using a hammer ( flat body work hammer works best ) tap the ruffled edge so that it comes to a 90 degree bend.

Step 4 – Heat the pan with a blow torch you should use Mapp gas not propane. Heat it until it turns a dark red. Work your way around the entire perimeter of the pan. This will remove the work hardening from the copper ( aka the bends and dents).

Step 5 – Get your hammer back out and re work the pan edge so that it is at a perfect 90 degrees to the bottom of the pan.

Step 6 – Get your blow torch back out and heat the entire pan up again to remove the work hardening we just introduced with the hammer. Heating the pan will slightly warp the bottom this can easily be flattened by hand or with a rubber mallet on a smooth flat surface.

Step 7 – Repeat this process for the Top pan and Flake stand

Here is a video that shows the Pan being built

Building the Frustum For the Pot Still

There are three frustums in this pot still design these include the top, bottom and cap frustum that need to be assembled. Follow the below instructions to do this ( * Note you can also build the flake stand wall following these steps ) :

Step 1 – Let’s start with the bottom frustum. Place a metal rod in the vice snug it tight, we will use this to shape the copper sheet we cut out for the bottom frustum. Slide the sheet from left to right over the rod while placing downward pressure on the sheet. This action should start to shape the copper sheet into an arc.

Step 2 – Use the bottom pan as a guide for the necessary curvature of the Frustum by placing it inside the Pan. You should have roughly a 1\2 ” overlap on the seam of the Frustum. Clamp the top of the seam in place and mark the bottom overlap while its sitting snugly in the bottom pan.

Step 3 – Remove bottom pan and clamp bottom of frustum on mark.

Step 4 – Using a ruler and a pencil mark the holes for the rivets along the seam of the Frustum. Space the rivets 1 inch on center along the entire length of the seam.

Step 5 – Drill out holes for rivets and rivet in place.

Check out this video which show’s the process of building the Frustum for the pot still.

Step 6 – Repeat these steps for the top and cap frustum and collar. Keep in mind you will need to drill a hole in the cap frustum before building it for the lyne arm to seat into.

Assembling All The Parts

Its time to assemble all the pieces to make the pot still.

Step 1 – Take the bottom pan and slide the bottom frustum inside the pan.

Step 2 – Rivet bottom pan in place.

Step 3 – Repeat these steps for the top pan and cap frustum ( see photo’s for more detail )

Step 4 – Slide the Lyne Arm through the hole you made in the top frustum and rivet into place

Step 5 – Rivet collar to top frustum

Step 6 – Assemble top and bottom frustum this is essentially the boiler of the pot still.

Step 7 – Solder all joints, make sure you don’t solder the head of the still to the boiler as this needs to remain in two pieces so that we can clean the still after it’s used.

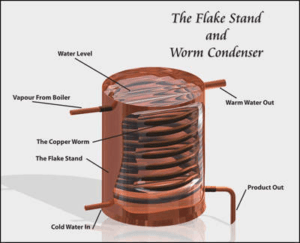

You’ve now completed building the pot still but we haven’t built the worm or stand yet. These are required to condense the distilled product that come’s out of the pot still.

Building the Flake Stand and Worm for the Pot Still

Step 1 – Insert flake stand wall into Flake pan and rivet pan and vertical seam in place.

Step 1 – Insert flake stand wall into Flake pan and rivet pan and vertical seam in place.

Step 2 – Using 1/4 ” copper tubing make a coil so it fits nicely inside the pan.

Step 3 – Drill 2 holes for the 1/4 ” copper worm. One at the top were the worm enters the flake stand and one at the bottom where it exits. ( This may be easier to do before it is assembled)

Step 4 – Place the Worm inside the Flake stand allowing the ends of the worm to stick out through the holes you just drilled. Solder these joints.

Step 5 – Drill another hole in the top of the Flake stand wall for a 1/2 copper pipe this will be the water outlet and one at the bottom for a water inlet. ( Attach these to your water supply )

Step 6 – Insert 1/2″ copper pipe to holes and solder in place.

Step 7 – Solder brass fitting on the inlet side of the worm. This will attach to the end of the Lyne arm on the Pot still. ( see images below for more detail )

That’s pretty much it I think! Below is a picture of the finished still you should now be seeing in front of you.

If you wish to us e this design to create a larger or smaller pot still you can alter the size of the original template by using this Scaling Chart to alter the size of your design.

e this design to create a larger or smaller pot still you can alter the size of the original template by using this Scaling Chart to alter the size of your design.

To learn how to use this pot still to make your favorite rum or whiskey head on over to the distilling section of our blog.

If your going to build this pot still I’d love to hear from you post any questions you have or photo’s of your still you’ve built below. If you’ve figured out a better way to build this still make sure you let me know !