How To Make A Sugar Wash

If you’re looking to make a simple neutral spirit like vodka, or just pure ethanol for hand sanitizer, using a sugar wash is highly recommended. This is because it’s simple to make and provides great results. There’s no point in paying more money for grains and malts not to mention the extra work involved with grain mashes, when you’ll strip all the flavour out using a column still.

You can make either vodka or rum with a sugar wash but remember if you plan to make rum you will need to use a pot still. For detailed instructions on how to make vodka or rum check out my two recipes below:

- Vodka Recipes – This one’s great for making high proof base sprites

- Rum Recipe – use a pot still and get a fantastic rum

How To Determine Final Alcohol content of Sugar Wash!

You can estimate the potential final alcohol content of the sugar wash by either measuring the specific gravity of the wash before fermentation is started or by using the calculator I’ve posted below. Just enter the amount of sugar and volume of water your using for the wash.

Calculating Potential Alcohol Content

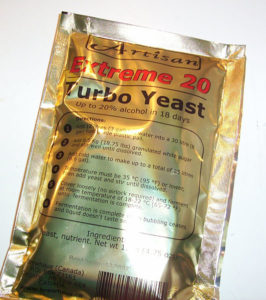

Selecting Proper Yeast for Sugar Wash

Every strain of yeast has a specific tolerance to alcohol content in the wash. The type of yeast you use will determine the amount of sugar that will ferment in the wash and the % of alcohol in your final product. The Yeast you choose to use in your sugar wash will determine the amount of Sugar you can add to your wash. For example simple brewers yeast for making beer can usually produce a wash to an alcohol content of around 12% where some turbo yeast can withstand alcohol concentrations of up to 23%. These turbo yeast allow you to use much more sugar and also get a larger volume of alcohol from the same volume of wash. If your interested in learning more about yeast selection have a read trough this article : Yeast selection for fermentation of sugar, grain and fruit.

The Importance of Yeast Nutrients

Refined sugar lacks the nutrients yeast need to reproduce. Without these nutrients the yeast will be unable to form sister cells causing poor fermentation. Also the alcohol produced will contain undesirable by products like higher order alcohols and aldehydes.

To be more specific yeast require minerals, enzymes and amino acids to reproduce so adding the yeast nutrients to your sugar wash is crucial for healthy fermentation. Some folks add tomato paste or vegemite to their sugar wash as a substitute however I always have the best results by using the yeast nutrients I get at my local brew shop.

5 Gallon Sugar Wash Recipe

Below is a basic five gallon sugar wash recipe that I’ve used in the past for making Vodka. I’ve outlined instructions from start to finish, this should make it very straight forward for you to follow.

Ingredients:

- 7kg White Sugar

- 5 Gallons Clean Water

- 1 Pack Turbo Yeast

You can use tap water however you should let it sit for a few days so that the chlorine can evaporate out. Don’t want to kill your yeast. If you’re on a well you’ll be fine.

Instructions:

- Heat up 2.5 Gallons of water so that it is hot, add sugar slowly so that it fully dissolves in the water. Warm water will dissolve the sugar with less effort.

- Pour contents into fermenting carboy or pail. Top up with remainder of water. Final temperature should be between 25 C to 30 C. You don’t want your wash to get hotter then 33 C or you’ll kill the yeast when you add it.

- Make a yeast starter

- Add starter to fermenting carboy and give light stir.

- Seal up with airlock and allow 5- 10 days to ferment.

Seal up the fermentor and add an air lock to the top this keeps out any unwanted bacteria but allows the gasses produce in the fermentation process to escape. Make sure you stays above 20 C while fermenting. If it dips below this temperature you could risk stalling the fermentation.

Fermentation can take anywhere from 1- 2 weeks depending on temperature and health of yeast. You’ll know when it’s done because the air lock will stop bubbling. The wash will look milky and if you taste it, it should have a strong alcohol flavour and lack any sugar as it should now be converted to alcohol.

If you prefer to watch a video of someone making a sugar wash, George over at Barley and Hops Brewing does a fantastic job of explaining things.

At this point your sugar wash is complete and it’s time to distill it. To learn how to distill your sugar wash check out our Distilling 101 resource section. If you’re new to distilling feel free to ask me any questions you have in the comments section below.